Custom Laser Cutting

Why Laser Cut a Pattern?

Laser-cut kits save you time, reduce labor costs, and give your customers beautiful, accurate results every time. Whether you're prepping for shop hops, launching a new product line, or just looking to streamline production, laser cutting helps you deliver more—with less effort. Our custom services ensure each kit is crafted to match your brand and meet your budget.

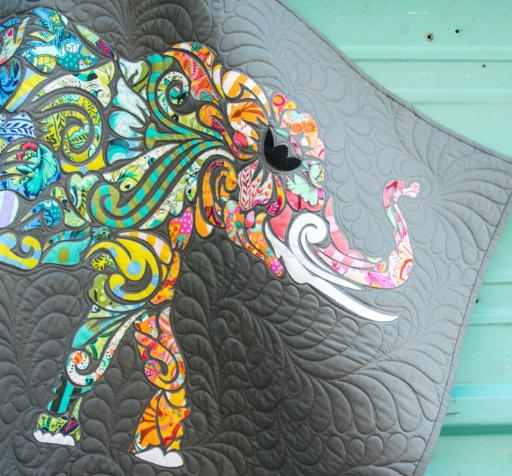

1. Your customers want more time: Applique is a time-consuming endeavor...but it doesn’t have to be that way. Check out Madi Hastings' design, “Holi Ganesha,” for example (pictured on the right). This pattern has over 100 pieces and took us only an hour at the studio to peel the paper and press each piece on the background. Compare that to two full days fusing, tracing, and cutting each intricate piece with a traditional applique method. Not to mention all the fabric you’d waste…

2. Saves $: I’ve heard a couple shop owners argue that laser cutting adds costs that they think customers wouldn’t pay for. But Rena, owner of Stitch n’ Snip, says,

“At my shop, I offer kits of the same pattern in wool and in laser-cut flannel. My ladies love the flannel because the cutting is done for them, and it’s a great selling point for us.”

She also noted that, “the laser saves fabric and labor costs, and that offsets the cost of laser cutting.”

Ready to see what laser cutting can do for your shop or brand?

HOW IT WORKS

1. We quote your project, after you provide us with:

+ An image of the project with dimensions OR full-size PDF pattern templates

+ Quantity (or range) your company needs

+ How you'd like your project kitted (bulk, individual, or retail) ----------------->

+ Any imminent deadlines for the project

2. You accept the quote by paying a 50% down payment

3. We send you fabric requirements

4. You send us fabric

5. We apply fusible to the fabric, laser-cut it, and collate kits according to your specs, including instructions for raw-edge fusible applique

6. We send the laser-cut kits back to your shop!

COPYRIGHT PROTECTION

We have a zero-tolerance policy for copyright infringement. Unless you are the designer of the pattern, we require proof of purchase of patterns before cutting (equal to at least the amount of kits ordered). Patterns must be included with each kit sold. In the event that the customer breaks copyright law, Laser Cut Quilts shall not be held liable.

OUR KITTING METHODS

1. Bulk Kitting: The least expensive method, pieces are cut and organized by color and put into a poly bag for you to collate yourself

2. Individual Kitting: Our most popular kitting method, all pieces of 1 kit are placed in a poly bag with an instruction insert

3. Retail Kitting: Our most customizable solution, involving collation of pattern, laser-cuts, and all additional fabrics needed to complete the quilt top; several packaging and finishing options are available--inquire if interested

Frequently Asked Questions

FlexiFuse is the highest quality iron-on fusible in the industry. It adheres well, protects the fabric and glue layers with the paper, peels off easily, and doesn’t gum up your sewing machines or get too bulky with multiple layers of applique.

Lead time depends on quantity of kits ordered.

A small order of 20 to 25 laser cut quilt kits has a one to two week turnaround

time upon receipt of fabric. Fill out our form above to request a free quote.

We’ll let you know pricing per kit and turnaround time.

Yes. We require a minimum of a 12 kit order to make it cost-effective for us and you. Do keep in mind that smaller quantities necessitate a higher price per kit. From our experience, cutting at least 24-48 kits is the best use of fabric.

Yes. Burning the edges of the fabric is desirable because it prevents the fabric from fraying during shipment and sewing. However, we have calibrated the lasers to burn at a low intensity and move more quickly than other lasers are capable of so that the “burn marks” are virtually unnoticeable, even on white fabrics. Also, some fabric manufacturers apply starches and other chemicals to their fabrics which can effect discoloration. For best results, send high quality quilting fabric for us to custom cut.

Yes; We send back all remaining fabric and extra pieces cut with your shipment of kits.

Yes. Each kit includes an instruction sheet

specifying temperature and time to press, along with other helpful applique

tips we’ve learned.

Yes! We love working with designers in their

creative process. Whether or not you order laser-cut kits, we can help design

vector files, templates, and layout guides for your designs. We have

large-scale printing capabilities as well.